DESCRIPTION

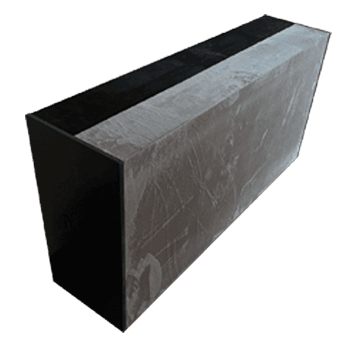

The creation of this bass trap patent and its manufacturing method consists of a very solid metal box, on which a bitumen elastic layer on each of the two sides is applied. The resonator's absorbing surfaces are thin massive plates: the front one with high elasticity and low internal friction and the back plate with less elasticity causing a high internal friction. This combination creates an all-over solid connection through the metal box between the front and back plates. This compound forms a box sealed all around, closed to the air pressure, but opened to the sound. The front and the back plates do not prevent the entering of low frequencies from going inside the box interacting with a different air pressure. Like a tunable Helmholtz resonator, the membrane is excited by the resonance frequency and it vibrates so strong that the weight of the limp mass pushes and pulls the air cushion inside the box.

The ABSTRACT resonance box formula comprises two limp elastic masses separated by the distance between them, benefiting the isothermal compression, thus providing better sensibility by absorbing the low-end frequencies at very low sound pressure levels. This system is very sensitive, however, the louder the sound system is, pumping the volume up, the more absorption you can get. Consequently it is an incredible high-efficiency low-frequency absorber panel.

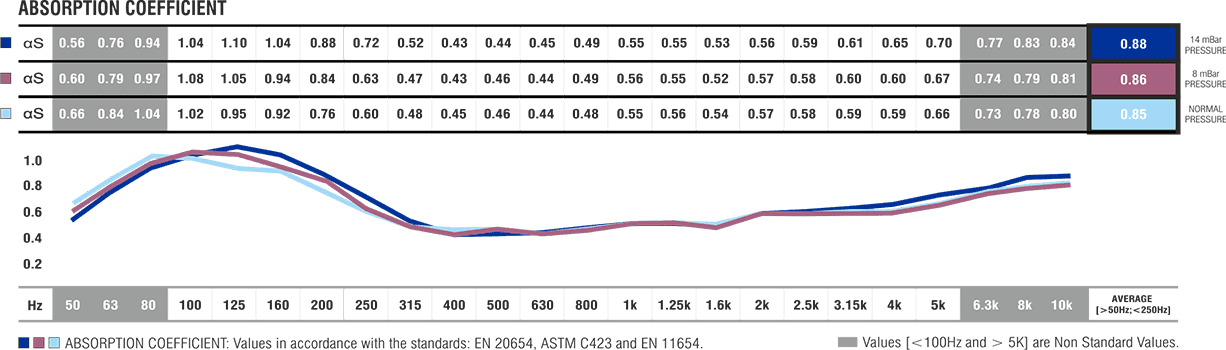

By using a simple air compressor device you are free to vary and change the internal air pressure, hence obtaining various different frequencies of absorption. The distance between the membranes varies according to the internal air pressure difference; for example with positive air pressurization we have a bigger distance and the air pressure superior to the original exterior pressure. As result, the frequency varies in accordance with the mentioned frequencies pattern.

In a more or less intense way, the problem of the low-frequencies control is widespread in most room types; This model is ideal for Concert venues, Auditoriums, Pavilions, studios, music rooms; these are the type of rooms that can greatly benefit from the integration of these acoustic modules, once they are the most effective and accurate way to intervene in solving the problems of low-frequencies.

FEATURES

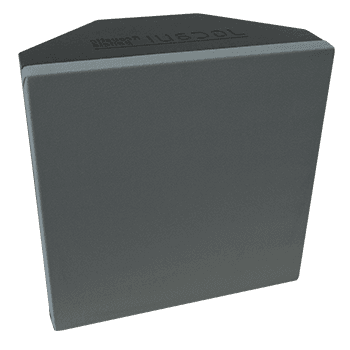

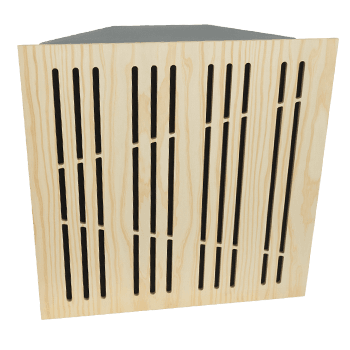

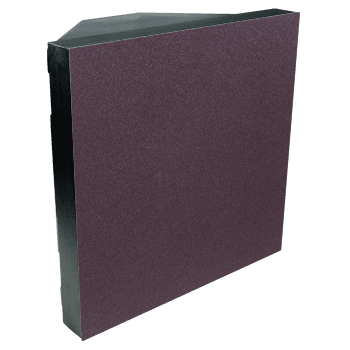

AVAILABLE FINISHINGS

Regular fabric:

Motif finishing:

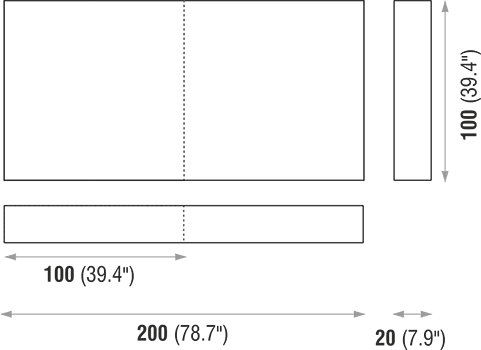

TECHNICAL DRAWINGS

PRODUCT DIMENSIONS

| Model | Height | Width | Depth | Weight | |

|---|---|---|---|---|---|

|

|

BSW100 | 100 cm (39,4") | 100 cm (39,4") | 20 cm (7,9") | 24 kg (52 lbs 15 oz) |

|

|

BSW200 | 200 cm (78,7") | 100 cm (39,4") | 20 cm (7,9") | 45 kg (99 lbs 3 oz) |

ABSORPTION COEFFICIENT

USED BY

PRODUCT DATA

Get in

touch

Text to us and tell us all your wishes

as your closest friend.

IMPORTANT NOTICE

IMPORTANT NOTICE

JOCAVI™ products are fire retardant and/or self extinguishing to varying extents. Before purchasing any of our acoustic foam products, please check with your local fire marshal or building inspector for approval. We cannot guarantee that any product meets the specific building code regulations in your area/country as regulations widely vary from place to place. JOCAVI™ will not be held liable for property damage or injuries caused by the misuse of our products.

Given the fragility and sensitivity of the raw materials used in the ATP™ product range, we advise and recommend these products are not installed within reach of physical contact by people or objects. Physical contact may damage these products.

Sizes may slightly vary due to their production method and some inherent raw-materials characteristics. Despite all the standard sizes of all products, some models can be customised upon previous consultation. Sizes may slighty vary due to their production method and some inherent raw-materials characteristics.